May 23rd, 2005 - Gutting The Fish

Now we're into some real meat. In fact I was surprised not to find any dead animals deep in the bowls of this thing.

Once again, sure to document the whole tear down, I slowly addressed each screw and found the pieces easily came apart. I could now see the mechanics behind this whole contraption. It seemed simple enough. You pull the draws and they actuate levers, and in turn those levers lift little doors allowing air to move out through them, giving the sound you want - hopefully.

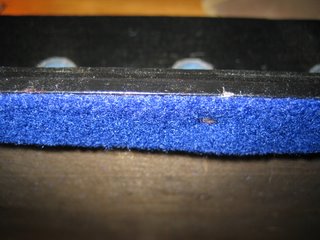

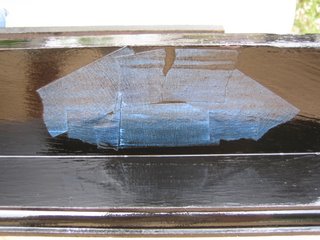

(This shows what is essentially the "valve cover" for the organ reeds. That seam along the left is a door which opens to allow air out. It is one of the pieces actuated by the draws. The taped seam on it is cracked and ineffective and needs to be replaced, however, I can't seem find a good replacement for it. The holes that run along the spine there are for a series of small pegs. The pegs reach down to the doors on the reeds and are depressed by the keys. The system's simplicity is remarkable.)

Down the line... the harmonics garage door

The felt here needs to be cleaned up, otherwise it looks pretty good. The reeds are all shiny and the wood on both the door and the floor is dry and solid. All I need is a vacuum cleaner.

Door Closed & Door Open

But before all that, the opening of doors, the moving of air, the creation of sound (per above paragraph), can happen the sound has got to get going in the first place and thus we dig deeper, into the reeds.

I discovered that the basic structure is on par with a 25 cent harmonica. A number of reeds all lined up and each sealed off, impervious to the air that is being pumped into the chamber below. That is until you depress on of your keys topside. This key pushes down upon a small dowel - about an inch long, if that, and rests in a tiny socket, aforementioned - and this dowel moves the small wooden slat out of the way allowing the air to rush though, in turn vibrating the reed to it's maximum potential, just like it's father would have liked.

Underside of "reed board" where the slew of slats sit.

A closer look - see the springs that hold the slats in place. One of these springs was off and causing problems. It was corrected. The wood down here is soft, really soft, kind of cheap, almost like a balsa. I'm curious if that's a sound thing or a less expensive thing or a high end thing? I'm curious as to the rational behind construction material here.

Another look - quite close now. Quite simple.

The wood slat or "Air Traffic Controller."

And finally a look inside at the reed it's self.

*Not a lot of work detail here - this was more of an exploration day.

**The "" names given are solely my creation and may not reflect the actual names of parts.